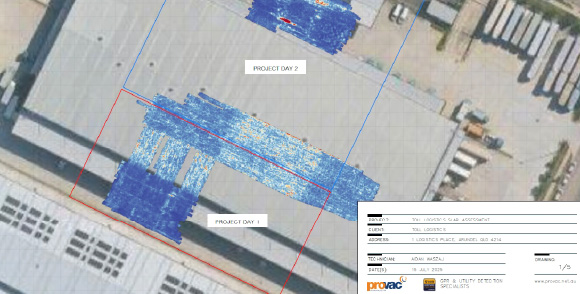

Client: Provac (collaborative project)

Location: Arundel, QLD

Date: July 2024

Equipment Used: IDS Stream C GPR, Total Station Survey Control, Geolitix Software

Project Background

South-East Scanning was engaged by Provac to assist in diagnosing suspected structural issues in a large industrial warehouse located in Arundel, Queensland. The warehouse slab exhibited visible signs of distress, including sagging, cracking, and general unevenness across the surface. These symptoms raised concerns about potential voiding, slab delamination, water ingress, or underlying soil instability.

Scope of Work

The scope of the project involved a comprehensive non-destructive ground penetrating radar (GPR) survey of:

- The internal warehouse slab

- The front apron

- The breezeway

- The surrounding carpark

The primary goal was to identify subsurface anomalies that may be contributing to differential settlement or structural fatigue, while providing accurate spatial data for further investigation or remediation planning.

Methodology

South-East Scanning deployed the IDS Stream C GPR system, a high-density multi-array scanner designed for large-area structural surveys. The survey was completed over two consecutive days, with a third day dedicated to post-processing and data interpretation.

Key elements of our workflow included:

- Total station survey control provided by Provac to ensure precise spatial accuracy

- Data capture in overlapping swaths to maximise resolution and reduce noise

- Post-processing in Geolitix, with depth slices, amplitude filtering, and anomaly classification

Findings

Although no major voids or cavitation zones were identified beneath the slab, these important observations were made:

- Moisture Ingress Indicators: Attenuated reflections and signal loss in specific zones indicated potential water accumulation or increased soil conductivity.

- Subtle Structural Deformation: Radargrams revealed mild variations in subsurface layering, correlating with observed surface dips.

- No Obvious Point Failure: The slab showed signs of generalised stress but lacked a concentrated void or sinkhole-like anomaly.

These insights allowed stakeholders to rule out catastrophic voiding and instead focus on monitoring and surface-level interventions.

Outcome and Recommendations

The final report provided Provac with:

- A high-confidence, non-invasive assessment of the slab’s subsurface integrity

- Georeferenced maps of flagged zones for future inspection

- Guidance for targeted coring or moisture testing to confirm radar-indicated saturation

The investigation ultimately helped avoid unnecessary full-slab excavation and supported a data-driven approach to ongoing site maintenance.

Project Highlights

- Full scan coverage across warehouse interior and exterior hardstand areas

- Coordinated fieldwork and data control with a trusted contracting partner

- Delivered within a tight three-day timeframe (2 days scanning, 1 day processing)

- Real-world demonstration of how multi-array GPR systems can assess industrial slab integrity efficiently

For more information on how we can help you with your project, or if you have queries about how we can assist you, don’t hesitate to get in touch with us!