Beneath the steel rails that crisscross our cities and countryside lies a complex network of materials and structures that ensure every train journey is safe, smooth, and on schedule. But like all infrastructure, railways and tunnels age, shift, and degrade over time – often in ways invisible to the naked eye.

Enter Ground Penetrating Radar (GPR) – a revolutionary non-destructive technology that allows rail authorities, engineers, and transport operators to see below the surface, providing vital insights into the stability and safety of tracks, tunnels, and surrounding ground conditions.

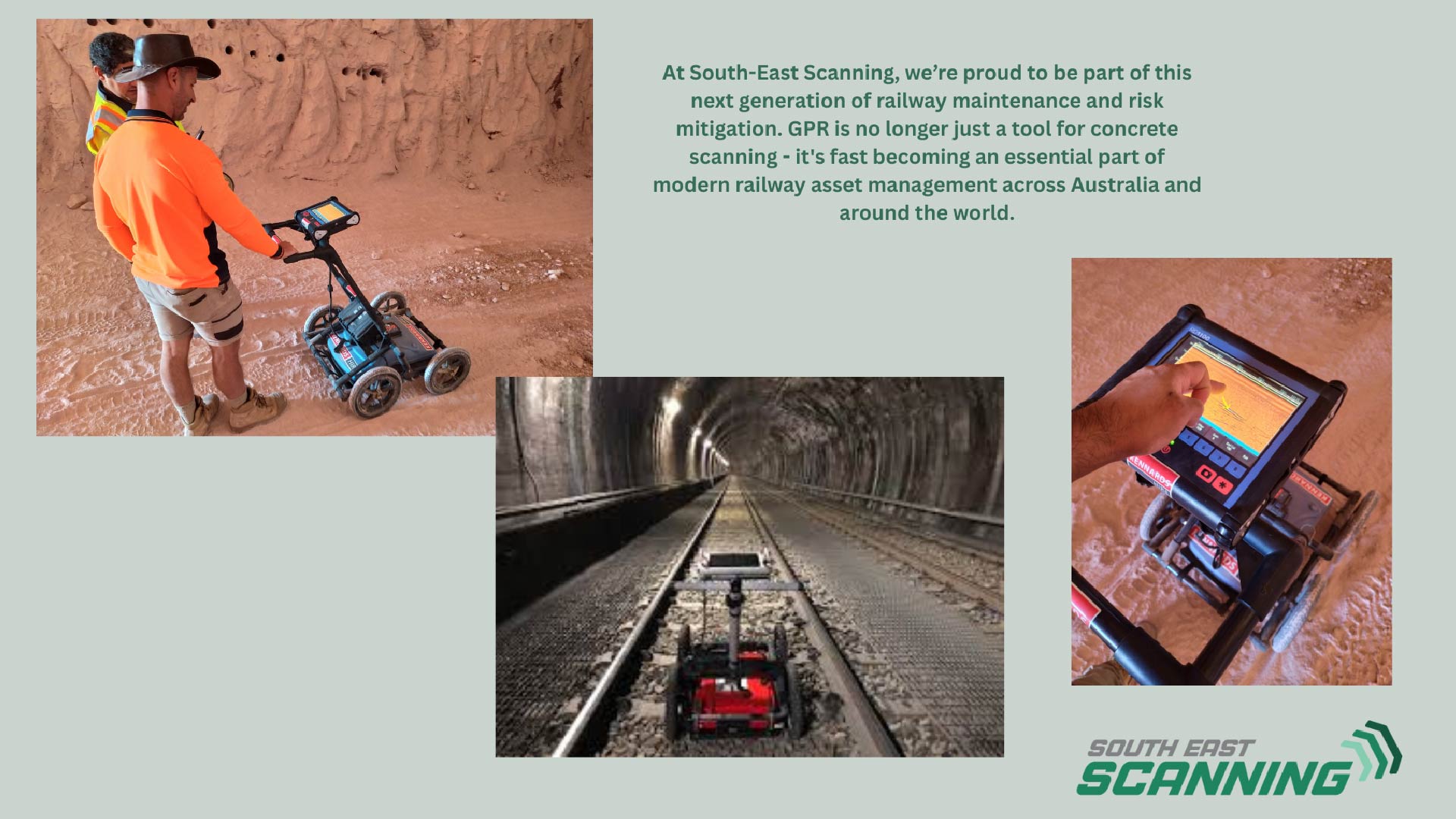

At South-East Scanning, we’re proud to be part of this next generation of railway maintenance and risk mitigation. GPR is no longer just a tool for concrete scanning – it’s fast becoming an essential part of modern railway asset management across Australia and around the world.

Why GPR Matters in Rail Infrastructure

Railways operate under immense pressure – both physically, due to the repeated weight of trains, and operationally, due to the constant need for uptime and reliability. Unlike roads or buildings, railway lines can’t be easily shut down for manual inspections or core drilling without significant disruption.

That’s where GPR offers a game-changing advantage. Using high- or low-frequency radar mounted on track vehicles or pushed manually, GPR can collect subsurface data at speed, without damaging the surface or stopping services. It gives engineers a clear window into the health of what lies beneath the rails – and it’s changing how railway maintenance is done.

Key Applications of GPR in Rail & Tunnel Work

1. Ballast Condition Assessment

Railway ballast – the crushed rock beneath tracks – plays a critical role in distributing loads, controlling water, and maintaining track geometry. Over time, ballast becomes fouled with fine particles, waterlogging, or organic matter, reducing its effectiveness.

GPR can assess the depth, density, and cleanliness of ballast, identifying sections that are compromised or need replacement. This enables targeted maintenance rather than full-track overhauls – saving money and keeping systems running.

2. Voids and Subsurface Defects

Voids beneath the rail subgrade can lead to dangerous track movement, misalignment, and even derailments. GPR can detect air gaps, soil loss, and uneven compaction that could signal structural failure beneath the rails or tunnel floors.

This early detection allows for pre-emptive repairs, extending the life of the track and reducing emergency closures.

3. Tunnel Integrity and Water Ingress

Australia’s growing network of urban tunnels – from metro lines in Brisbane and Sydney to ageing freight corridors – faces risks from moisture infiltration, delamination of concrete linings, and soil instability.

GPR scanning along tunnel walls and crowns can map moisture patterns, cracks, and construction anomalies, providing data critical to tunnel asset managers. Combined with other non-destructive methods, GPR contributes to ongoing tunnel lifecycle management.

4. Locating Buried Infrastructure Along Rail Corridors

Utilities often run alongside or beneath railway lines, including drainage, power conduits, and signalling cables. GPR can safely detect these assets during upgrade projects or electrification works, thereby avoiding costly strikes and delays.

A Real-World Example: Sunshine Coast to Brisbane Corridor

On a recent scanning job along a regional corridor north of Brisbane, our team used GPR to assess a section of ageing ballast near a curve with known water issues. Within minutes, the system identified significant ballast fouling and subsurface voids forming under the outer rail.

Our findings allowed engineers to stabilise and recompact the area – preventing what could have become a major service issue. It’s a powerful reminder that preventative GPR scanning isn’t just about data – it’s about people’s lives.

Integrating GPR with Other Rail Safety Technologies

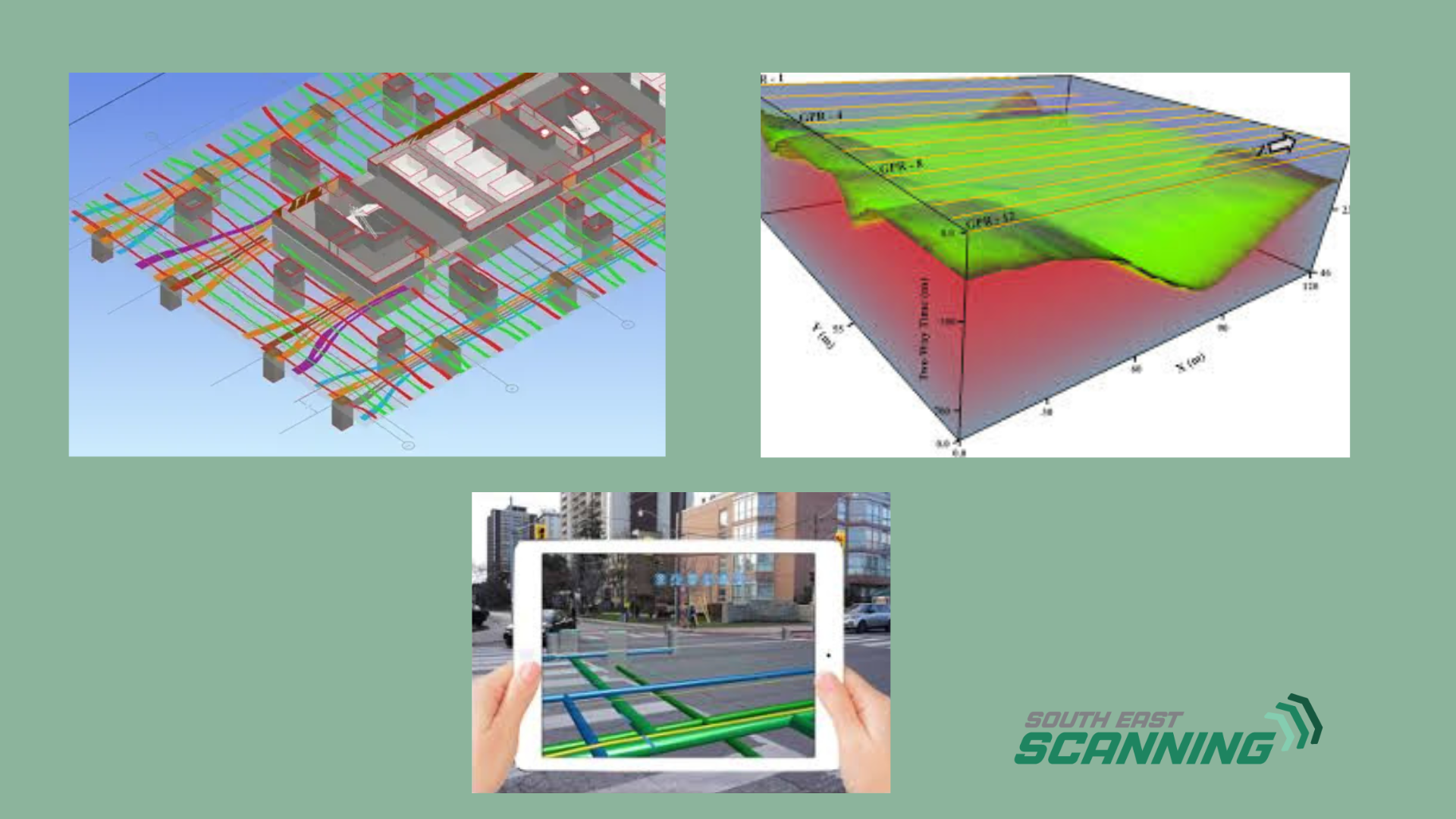

GPR doesn’t operate in a vacuum. When integrated with LiDAR, inertial measurement units (IMUs), high-resolution video, and GPS, a complete digital twin of the rail network can be created. This opens the door to predictive maintenance, AI-powered risk scoring, and more innovative budgeting across rail asset portfolios.

In the future, we envision drone-mounted GPR units scanning difficult-to-access bridges and mountain tunnels, while AI algorithms review real-time scans to flag anomalies automatically.

Why Rail Authorities Are Taking Notice

From Queensland Rail to Sydney Metro, transport authorities are investing in modernisation – and that includes smarter, faster subsurface investigations. The move toward condition-based maintenance, instead of fixed schedules, requires deeper visibility – and GPR is the key.

Even heritage railways and regional councils are now recognising that GPR scanning offers better safety, lower long-term costs, and stronger compliance with regulations.

How South-East Scanning Can Help

Our team is equipped with state-of-the-art GPR systems – including high-speed cart-based systems and portable units – suitable for both on-track scanning and tunnel inspections. We work closely with rail engineers, asset managers, and safety officers to deliver clear, actionable reports and real-world insights.

Whether you’re planning a significant upgrade, managing an ageing line, or seeking early warning signs of subsurface problems, South-East Scanning has the experience to support your goals.

GPR is no longer a “nice-to-have” in railway asset management – it’s a mission-critical tool that keeps our trains running safely, smoothly, and sustainably. In a world where time, safety, and budgets are constantly under pressure, subsurface visibility is more valuable than ever.

If your rail project involves tunnelling, ballast replacement, or corridor upgrades – let’s talk. We’ll help you see what lies beneath, before it becomes a problem on the surface.